July 10, 2018

Para-what? Meet the Parametric Design Wizards Who Make Tylko Tick

From the initial sketches to final delivery, parametric design plays a part of nearly everything we do at Tylko. But what exactly does it mean?

Parametrics is a word you might have heard tossed around quite a bit lately. If you’re not 100% sure what it actually means, you’re not alone! We sat down with with Tomasz Gancarczyk and Jonasz Kulej of Tylko’s Parametric Team to learn the layman’s secrets of this exciting area of expertise.

You’re definitely the most mysterious department at Tylko. What exactly does the parametrics team do?

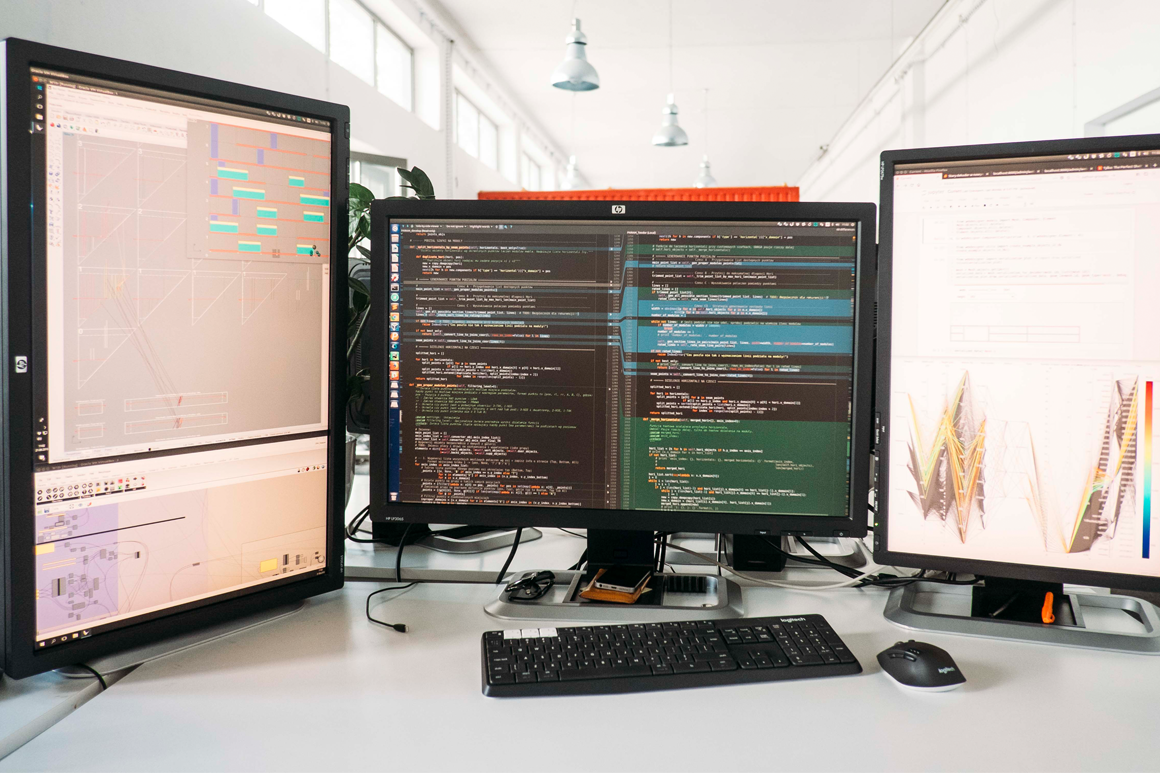

Tomasz: We’re actually a part of a nearly all of the company’s operations, and we combine design with coding – mostly due to the custom-made approach at Tylko. From the first sketches in the design department, through the IT solutions, production, and even business analyses – we need to build and implement solutions using parametric models. Our most important task, however, is to transform the designers’ work into customizable models that our customers see in the configurator on Tylko’s website, of course.

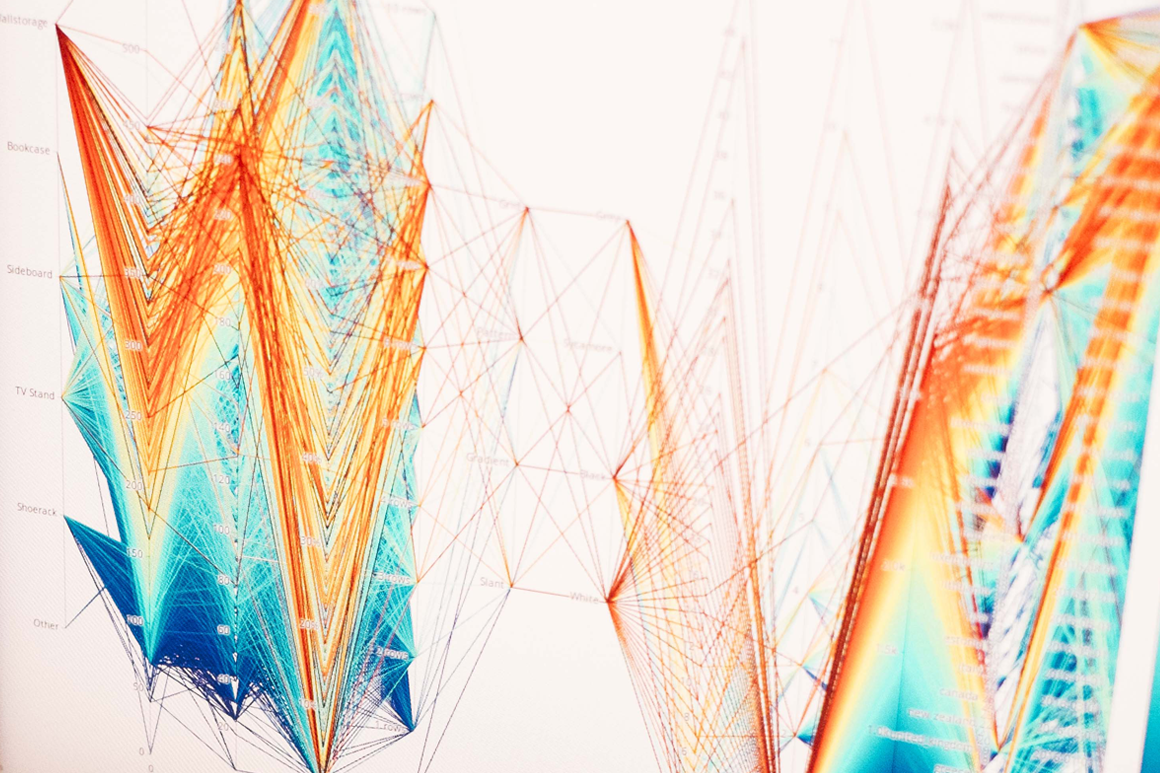

Jonasz: But we also analyze and interpret customer behavior, the configuration process and even shopping trends. We care for the less-visible aspects of the Tylko experience too, including the assembly process. For each piece a customer orders, we automatically generate a personalized assembly manual and make sure that all the packages are labeled and presented to the customers in an easy and simple way.

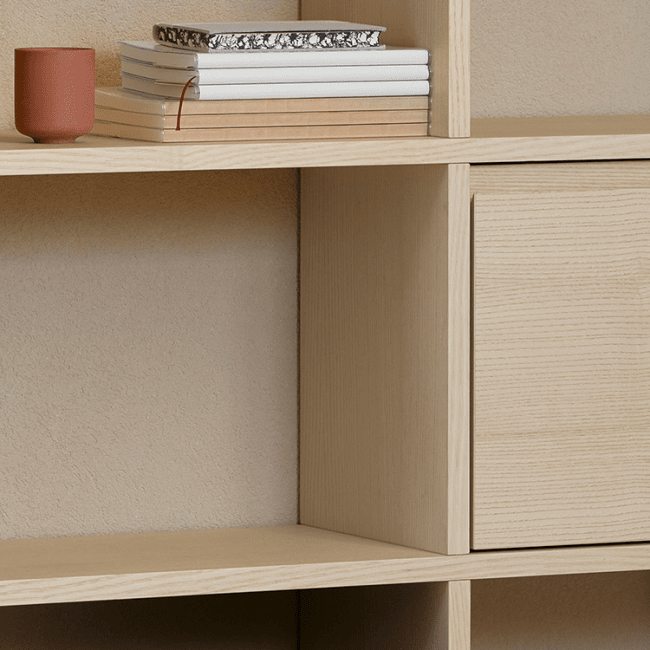

What are the benefits of choosing a parametrically designed piece of furniture?

T: When you buy a traditional piece of furniture, one of the main problems is that we can’t personalize it to match our individual needs. The process of searching for the right product is often long and arduous. It typically ends with a compromise between the look we want and the available sizes and functionality. The alternative solution – furniture made by a carpenter – is just as tricky. The quality might be difficult to verify, deadlines might not be met, the price can be exorbitant, etc…

And this is where you come in with parametrics?

J: Yes! Products based on parametric models are a perfect combination of the advantages of designer, made-to-measure furniture combined with the quality and price of batch production. And, we gain great flexibility and freedom to change and adapt our shelves to the customer’s needs and expectations.

Can you share the most interesting aspects of creating parametrically-designed furniture?

T: Working with the design department is always intriguing. Regardless of the amount of sketches and talks at the concept stage, once you move to the final process of creating a parametric model, thousands of issues, exceptions and necessary improvements always crop up.

J: The biggest challenge of the entire process is to ensure the appropriate design quality and functionality in each of the millions of product variations. Checking such a high number of options by hand is impossible, so at the last stage of the design process, each furniture option is carefully analyzed by our algorithms. to verify their strength and aesthetic and functional quality. Some of the furniture configured by our customers often turns out to be something new and surprising for us – they create individual and unique combinations, but neither we nor any human has seen them before – just our algorithms!

What do you think is going to happen next in the world of parametric design?

J: I believe that the next step is to integrate the tools that are already available (for example parametric models, VR, AR, generativity and natural language) and develop them into a comprehensive platform that would utilize any type of information at all – like the scan of a room, for example – to generate a unique, perfectly-personalized solution that from the get-go doesn’t require the user’s initial configuration.

Tomasz Gancarczyk

Graduated from the Faculty of Architecture in Warsaw, and has been a Parametric Designer with Tylko since 2015. His work meets at the juncture of two worlds: the digital (IT, code, data, new technologies, automation) and the analog (designing sites and spaces, and their function in the real world). He sees interesting new possibilities and a great future for designers who work in connecting these two worlds.

Jonasz Kulej

Graduated from the Faculty of Architecture at Warsaw University of Technology and the Silesian University of Technology. After a few years of running his own design studio and searching for optimal solutions through the use of computational design in everyday architecture, he turned to the optimization of design processes, purchasing and furniture production at Tylko. A few years on, he still enjoys discovering new challenges encountered on the path set by Tylko.